Buildup Welding Works

Buildup Welding Works

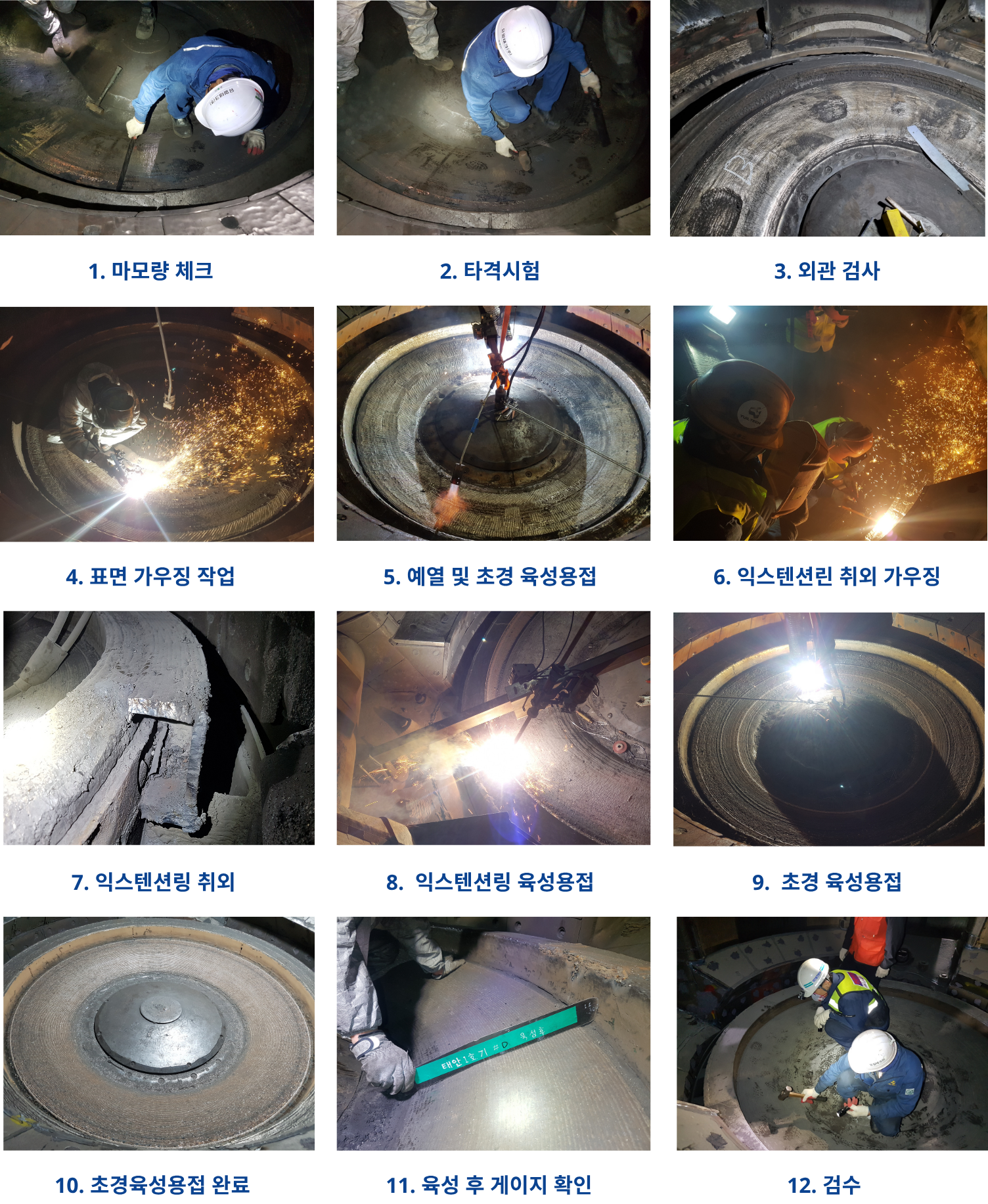

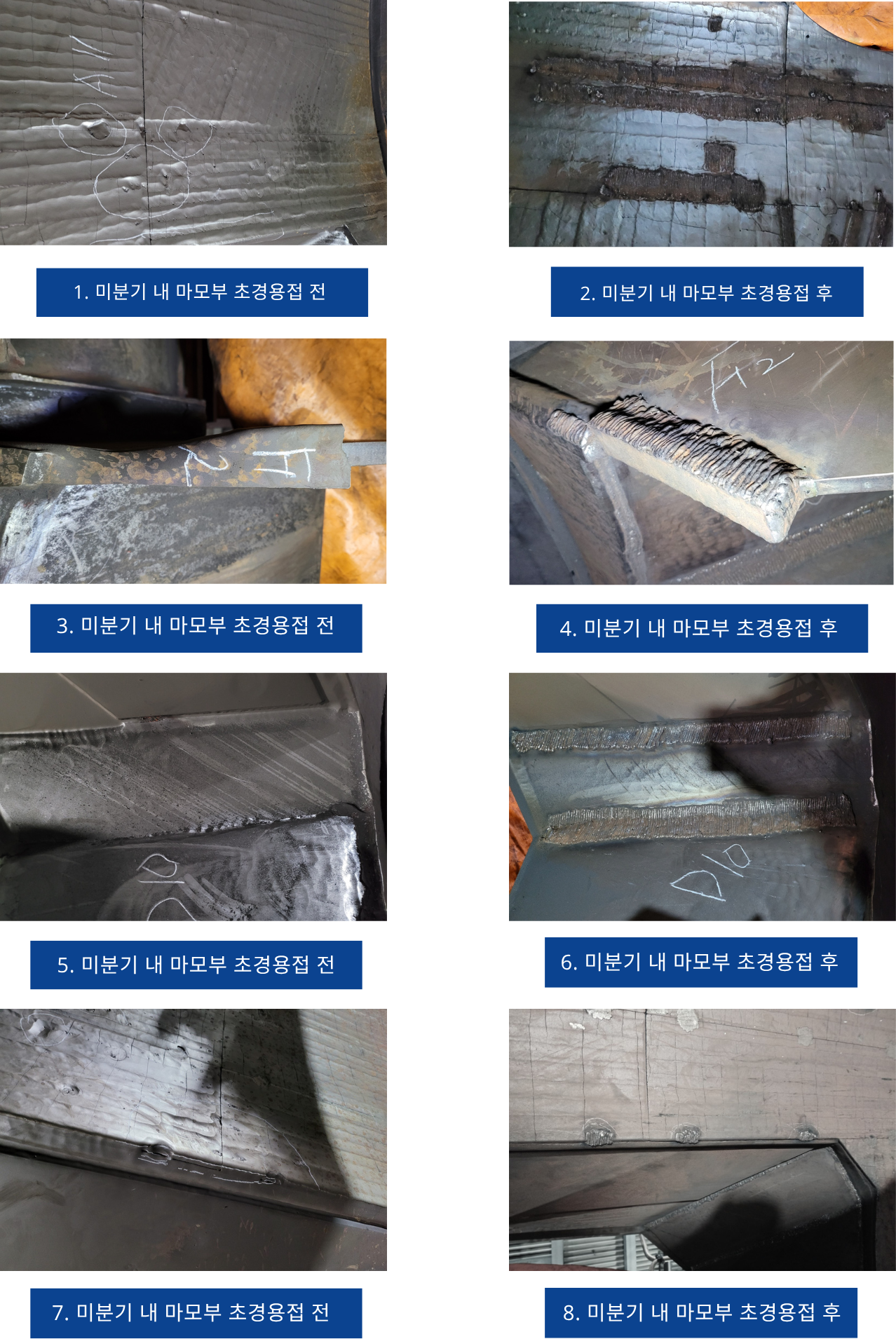

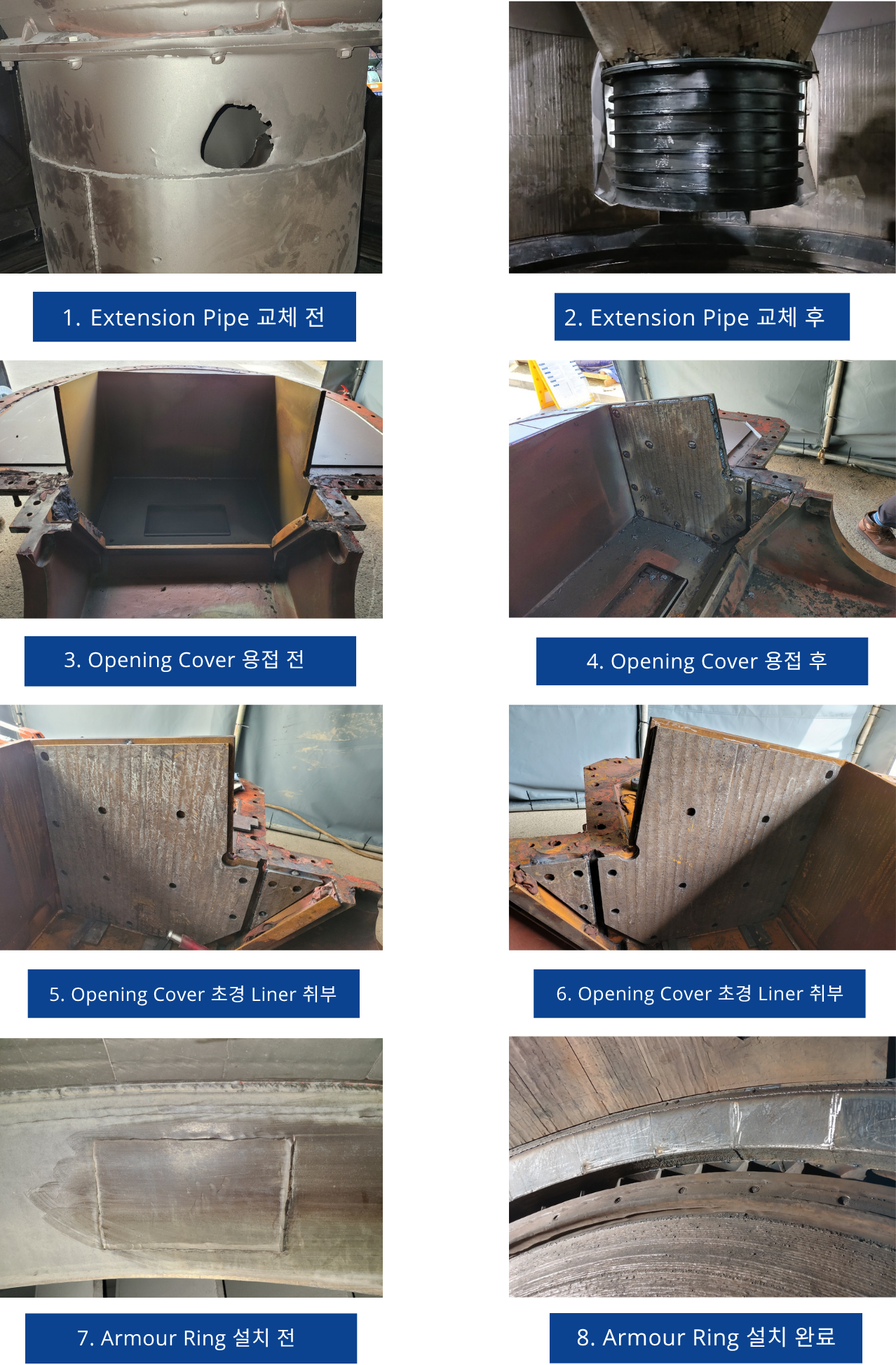

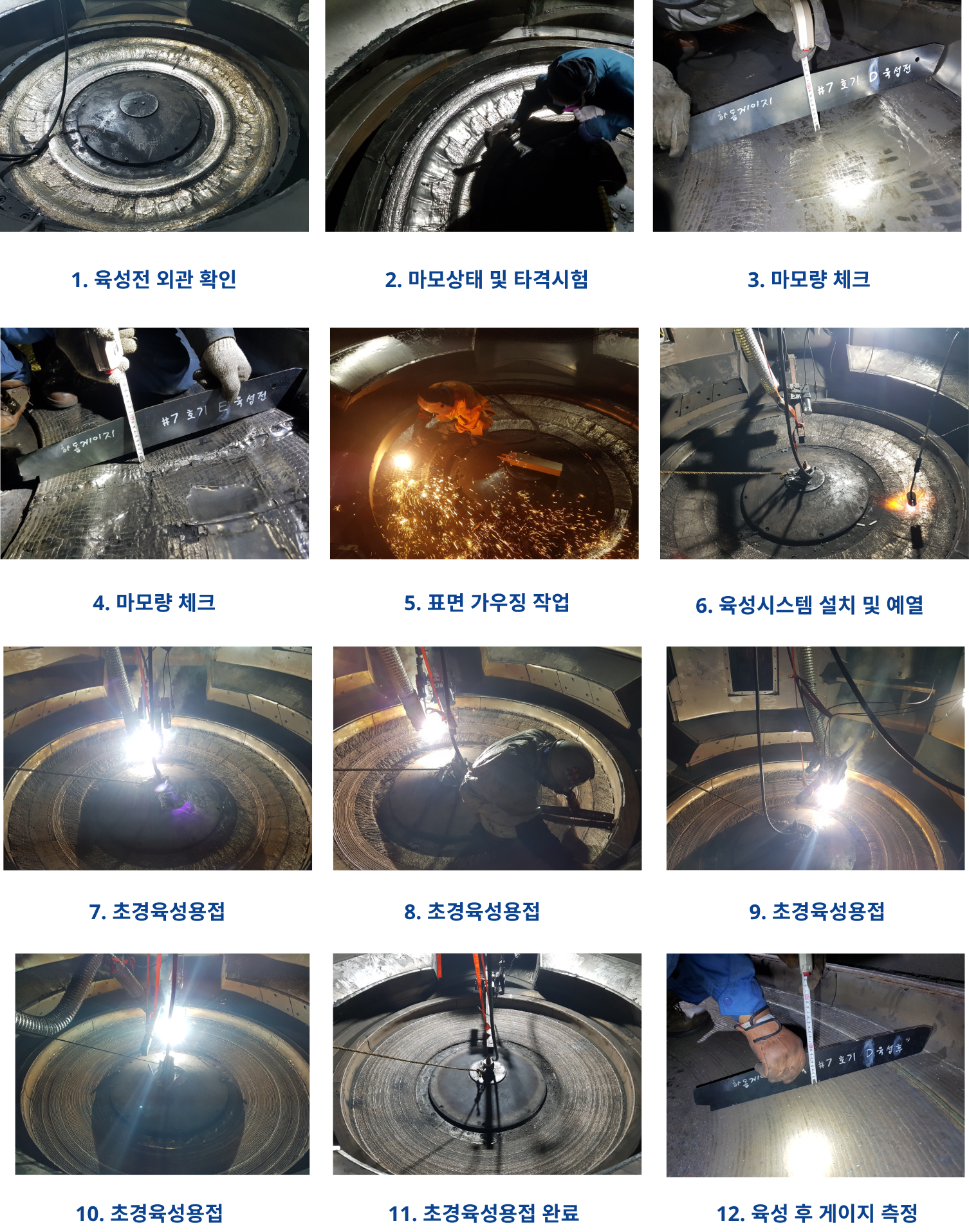

Yuil Tech performs advanced buildup welding works for key wear components such as Grinding Roll Tire and Grinding Bowl in pulverizer systems of power plants.

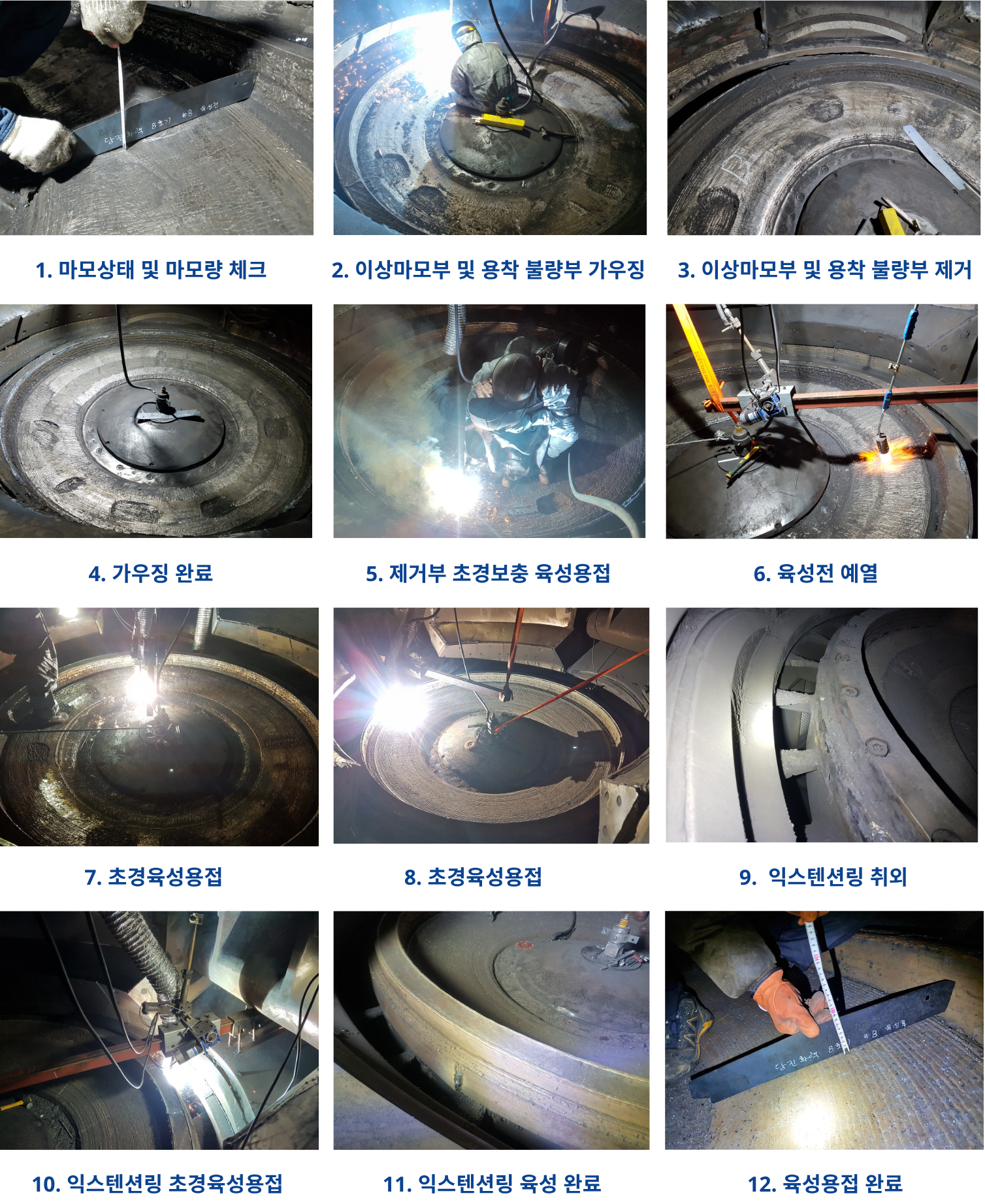

After disassembly, the Roll Tire is transferred to Yuil Tech’s main factory, where a precision buildup welding process using high-hardness special alloy is carried out automatically.

The Grinding Bowl can be welded on-site or off-site, depending on customer requirements

Buildup welding restores worn surfaces, extending service life from 20,000 up to 32,000 hours. Yuil Tech’s experienced technicians ensure top-level quality and reliability in wear-resistance performance.

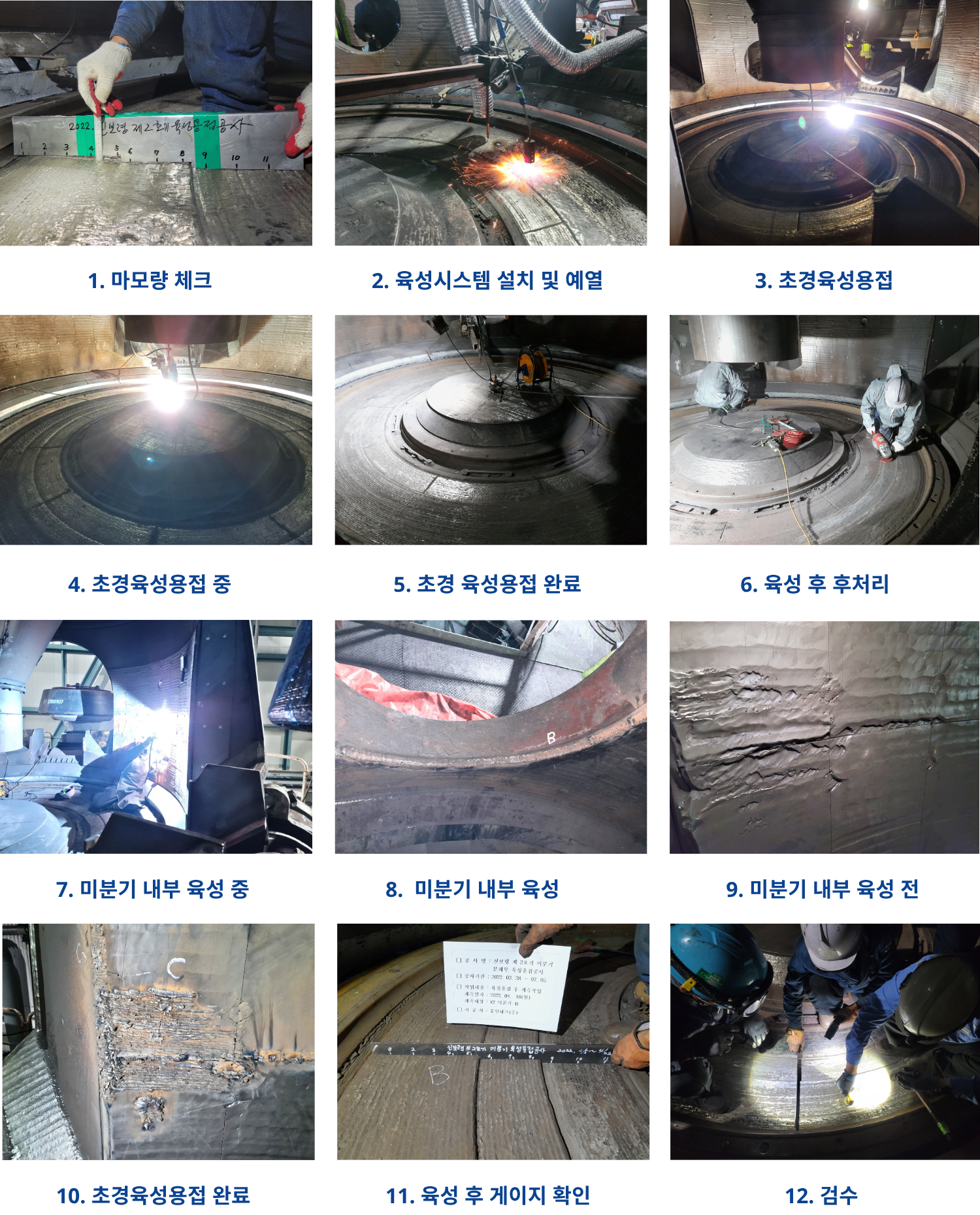

Yeongheung Thermal Power Plant Units #5,6 Ultra-Thin Overlay Welding Project (LM-35)

Yeongheung Thermal Power Plant Units #5,6 Ultra-Thin Overlay Welding Project (LM-35)

Welding Work for Grinding Section of Five Power Generation Companies' Unfinished Parts HP1183-1203 (Namdong Power Generation Yeongheung)

Welding Work for Grinding Section of Five Power Generation Companies' Unfinished Parts HP-923 (Korea Southern Power Hadong)

Welding Work for Grinding Section of Five Power Generation Companies' Unfinished Parts HP-923 (Installation at Hadong New Plant, Korea Southern Power)

Welding Work for Grinding Section of Five Power Generation Companies' Unfinished Parts HP-923 (Dongseo Power Generation Dangjin)

LM-35.3D Welding Work for Grinding Section of Five Power Generation Companies' Unfinished Parts (Korea Midland Power Sinboryeong)

Welding Work for Grinding Section of Five Power Generation Companies' Unfinished Parts HP-883 (Korea Western Power Co., Taean)